This Is Our Expertise.

Empire Metal Works is one of the few fabrication companies in the North-East that have the ability to do projects on the scale and quality as us. If our team says we can handle the work you are requesting, we can – and we will.

We Are Ready to Take on your project.

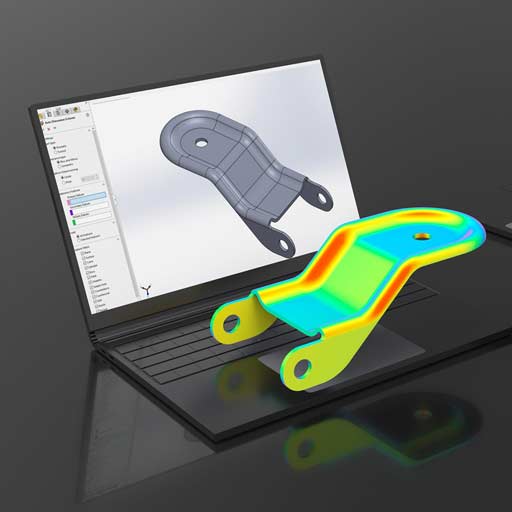

Our engineering department uses state-of-the-art modeling software to release accurate and easily understandable prints for your projects components. With over 40+ years of experience, knowing the optimal way to put a sheet metal structure together means your business saves money.

- Our equipment are state of the art.

- Our employees are highly skilled, and motivated.

- We have the ability to cordinate shipping globally.

- Our pricing is highly competitive.

- 30 William St, Walton, NY 13856

- Mon - Fri : 7:00 am - 3:30 pm

- (607) 865-4031